Custom Plastic Phone Cases in casefty

Casefty produces and customizes plastic mobile phone cases, providing customization of mainstream IMD mobile phone cases, UV mobile phone cases, thermal sublimation mobile phone cases, and epoxy mobile phone cases. The biggest advantage of plastic mobile phone cases is their strong plasticity, which can be compatible with various printing methods and can be mass-produced by injection molding.

Custom Plastic Phone Cases

The customization of plastic mobile phone cases can be divided into two categories: customization of surface printing and customization of functions and materials. Regarding surface printing, we provide solutions such as UV printing, thermal sublimation printing, and IMD/IML technology, which can be selected according to each different characteristic. Regarding functions and materials, we offer TPU/PC and TPE materials to create your mobile phone case project. The transparency, lens protection, anti-slip, waterproof, radiation protection, and other functions of the mobile phone case can be customized, and the feel of the material can also be adjusted. We welcome you to send us drawings to evaluate your project; of course, this is absolutely confidential.

- UV printing phone case: one model, One print; minimum order: 20.

- Sublimation phone case: one model, One print; minimum order: 20.

- IMD phone case: one model, one design; minimum order: 20.

- Handmade glue phone case: one model, one design; minimum order: 20.

- Open mold products 300-500 single model MOQ.

- For the rest of plastic 3c accessories, ask our sales.

- Customized printing

- customized materials

- customized functions

Premium printing

High-quality printing results

Function

Function customization

Surface Technology

Oil spray or frosted options available

Anti-yellowing

TPU delays yellowing

Customized by Production method

UV-printing phone cases

UV-printed mobile phone cases have low minimum order quantities and low costs, making them most suitable for brands to test the market in the early stages.

Sublimation phone case

The color effect of thermal sublimation mobile phone case is the best among all current printing methods and is suitable for fashion brands.

IMD Phone Case

You don’t have to worry about the pattern being damaged on the IMD phone case, and the two layers of printing can create a very cool effect.

Handmade glue phone case

The handmade glue phone case can completely seal everything in nature on the back of the phone case

Customized Plastic phone case finished product

Here are some reference pictures of plastic phone case projects

The advantages of choosing casefty

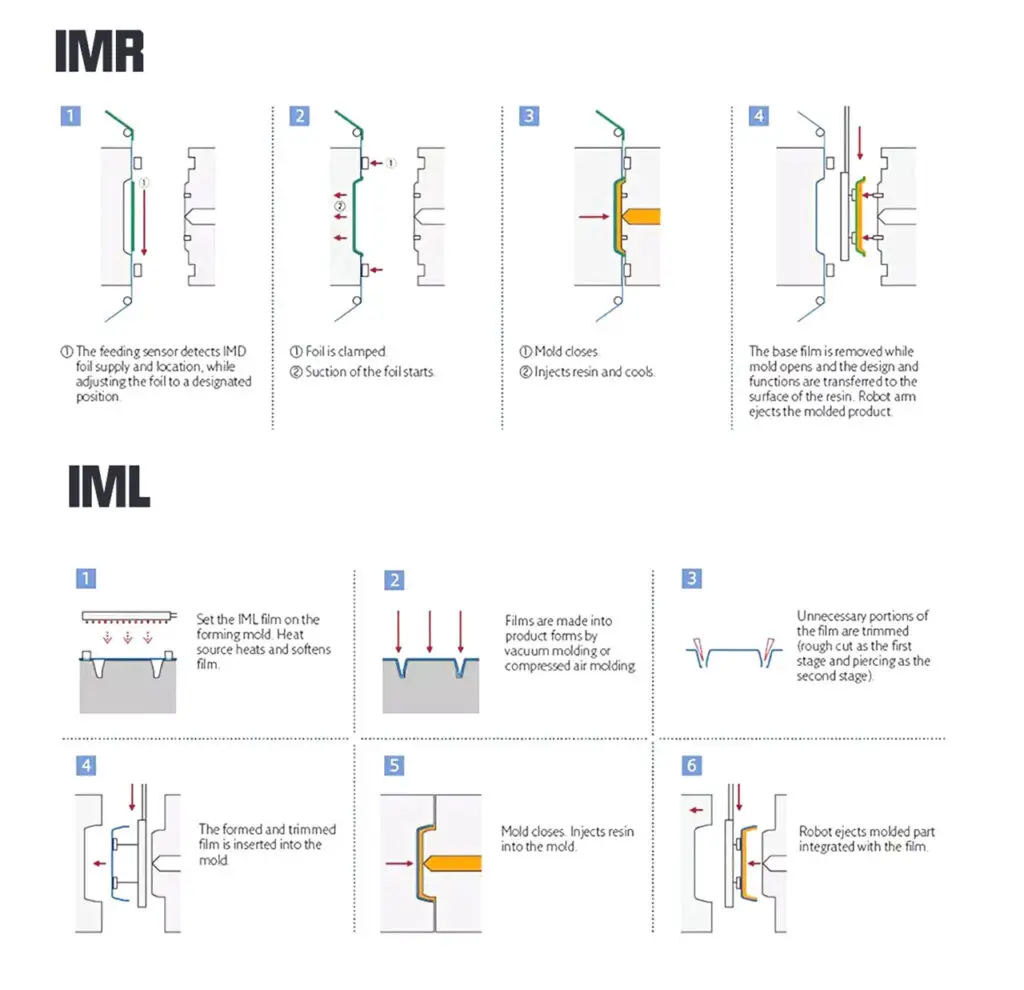

In-membrane decoration technology

In-mold decoration technology is a great surface decoration technology. In the past, no matter what kind of printing was used, it would fade and become damaged over time. IMD technology directly leaves the printing layer inside the plastic product through injection molding, isolating the printing layer from the air and the oxidation reaction from the outside world, ensuring that the printing layer will never be scratched or faded. Additionally, two layers of printing can be injected at the same time, producing amazing visual effects.

- Never fade

- Double layer printing

- Anti-scratch

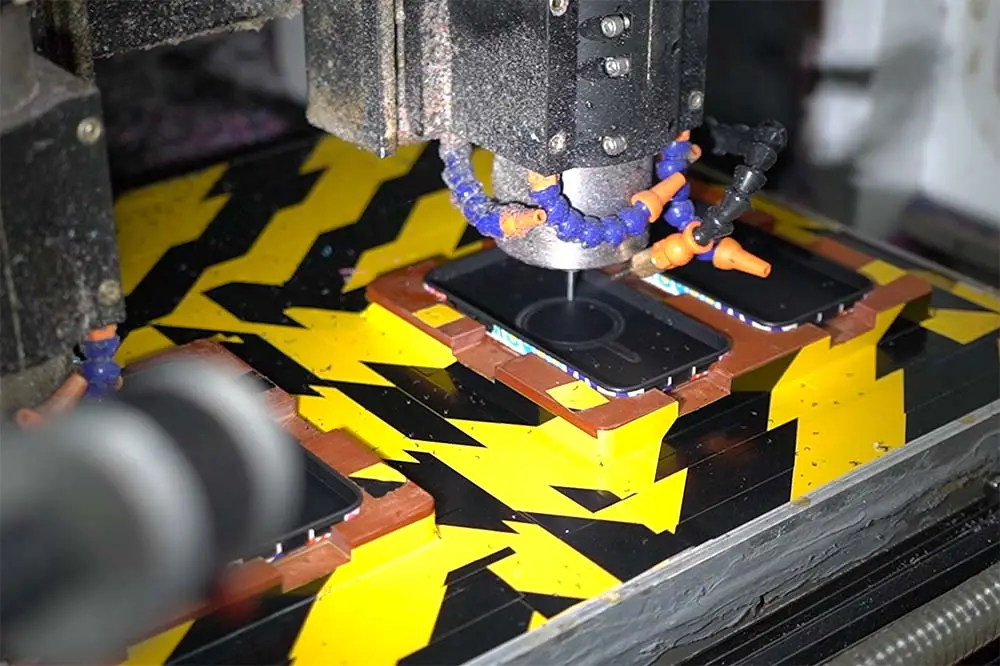

Precision machining capabilities

The manufacturing of a multifunctional mobile phone case often involves more than one process; rather, it requires the cooperation of multiple processes. We have strong reprocessing capabilities, and each process is closely connected. Additionally, we have a high-quality quality management system.