Table of Contents

Introduction

Whether you are buying a mobile phone case for your own use or for your mobile phone case business, you need to understand all types of mobile phone cases before you can make a better choice. However, the current mobile phone case market is dazzling, and no one can cover all mobile phone cases. To give a clear explanation of the categories, in this article, youcasefactory will use its more than ten years of manufacturing experience to tell you what types of mobile phone cases there are, what characteristics each type has, and how to choose the one that best suits you mobile phone case to start customizing a mobile phone case that suits you.

There are currently so many types of mobile phone cases that it is difficult to describe them clearly from just one perspective. Therefore, youcasefactory will explain the types of mobile phone cases from four perspectives: materials, manufacturing methods, effects and functions. After reading this, you can make the decision to customize your phone case.

types of phone cases

By material

According to materials, there are the following types of mobile phone cases:

Plastic Phone Case (Pc Tpu Tpe)

Plastic mobile phone cases are currently the mainstream mobile phone case manufacturing material, and they are also the most abundant type of mobile phone cases. Most of them are made of thermoplastics. Generally, hard plastic PC or ABS and soft plastic TPU or TPE are used to make mobile phone cases. . Plastic mobile phone cases have the following characteristics

Mature manufacturing technology: currently there are 3D sublimation, UV printing, IMD, Epoxy, water stickers, etc.

Low cost of high-volume manufacturing: Once professional molds are developed, the cost of high-volume manufacturing is very low.

Rich customization options: The process of making effects on plastic mobile phone cases is very mature. The customization of injection molded sheets allows plastic mobile phone cases to achieve almost any visual effect. The effects that have been achieved so far include 3D, electroplating, color plating, holographic, etc.

silicone phone case

It refers to a mobile phone case made of silicone as a raw material. Silicone is a rubber-like synthetic material known for its toughness, durability and shock-absorbing properties. Mobile phone cases made of silicone have the following characteristics:

Skin-friendly: It feels very good and feels like skin. No one will feel any discomfort when they get the silicone phone case.

Lightweight: The silicone phone case is very light and weighs almost nothing, which is good news for people who care about the weight of their phones.

Anti-slip: Due to the special nature of its material, the silicone phone case is difficult to move on any smooth surface, preventing the phone from falling due to sliding.

Anti-fall: Silicone itself has a certain degree of toughness and considerable buffering properties, which can prevent damage to the phone caused by falling to a certain extent.

Safety: Inferior silicone phone cases contain carcinogens! So choose your supplier carefully. The silicone mobile phones provided by youcasefactory have reached food safety level, allowing us to say goodbye to carcinogens!

leather phone case

Leather mobile phone cases refer to mobile phone cases made of genuine leather or artificial leather. Leather mobile phone cases naturally give people an original and high-end feeling. The skin used for mobile phone cases can be the outer skin of animals, or the second layer of skin or inner skin of animals. You can choose according to your own preferences. The following are some characteristics of leather mobile phone cases.

Metal phone case

Metal mobile phone cases refer to using metal materials to make mobile phone cases, but ordinary metal materials are relatively heavy, so many ways may be used to lighten them. For example, you can punch holes in areas that are not directly protected by the phone case, or use lighter mixed alloy materials. The following are the characteristics of metal phone cases.

Good heat dissipation: Metal materials have strong thermal conductivity. All computer radiators are made of metal, so they can better dissipate heat for mobile phones and avoid performance degradation caused by excessive heat.

Strong: The metal itself has very high strength. When using a metal phone case, you no longer need to worry about the phone bending. However, metal does not have toughness, so in order to ensure the drop protection performance of the metal phone case, cushioning plastic will be added to the corners as needed.

Environmentally friendly material mobile phone case

Environmentally friendly material mobile phone cases refer to using environmentally friendly materials to make mobile phone cases. Through special processing, environmentally friendly material mobile phone cases can also have customized colors and patterns.

Environmentally friendly materials are

Cocoa Bean Waste: Cocoa Bean Waste is an ecological alternative to the industrial waste generated by the chocolate industry, offering durability and excellent insulating properties

Plant fiber: Most plant fibers can be used to make mobile phone cases

Pineapple fiber: making mobile phone cases has a feeling close to leather

Hemp: Hemp fiber cell phone cases have a special smell.

Theoretically, youcasefactory can make mobile phone cases from any material, so if a lot of materials are wasted in your business, why not let us make a mobile phone case for you, and it will become a product that everyone loves

by manufacturing method

3D sublimation phone case

What is a 3D sublimation phone case?

3D thermal transfer mobile phone cases are also called film mobile phone cases. It refers to a technology that uses high temperature and high pressure to sublimate design drawings onto mobile phone case models of specific materials. It can achieve vibrant colors and will not fade. It was first invented by a Korean factory. , and can only be used for hard phone cases made of specific materials. With the development of technology, youcasefactoy has now invented a soft phone case that can be used for 3D sublimation.

Features of 3D sublimation mobile phone case.

Bright colors: 3D thermal transfer phone cases can directly realize RBG color gamut on objects. If you don’t need spot colors, but just need strong visual impact, then 3D sublimation phone cases are the phone cases you must consider.

3d sublimation vs sublimation

3D sublimation refers to wrapping the pattern on the back and sides of the phone case while sublimating the pattern. Subimation only refers to sublimating the pattern on a separate back.

3d sublimation vs uv printing

The colors of 3D sublimation are more vibrant, but it is difficult to calibrate the colors, and there is no way to set the thickness of a specific color. UV printing is not so dynamic but has high color accuracy and easy color correction. You can also raise the pigment by 2 to 6mm as needed.

uv print phone case

UV printing of mobile phone cases uses specific UV inks to print on the surface of the mobile phone case, coupled with UV light irradiation, each color of ink dries instantly when passing through the UV light, making the CMYK four-color superposition clearer and preventing the inks from merging with each other. resulting in a clear picture.

Features of uv mobile phone case

Clear: Each color is colored individually without mixing, ensuring a clear image

Spot color: Because it uses cmyk color transfer printing, it can 100% restore the original design file. It is a must-choose printing method in the design industry.

Relief: UV printing mobile phone cases can currently print a 4-8mm relief effect, making the surface pattern more textured.

Low minimum order quantity: The minimum order quantity for uv printed mobile phone cases is very low. Youcasefactory can provide a single model with a minimum order quantity of 50 mobile phone cases.

At present, most of caseftiy‘s mobile phone cases are basically UV printed.

imd (iml)phone case

In-mold decorative mobile phone cases refer to mobile phone cases in which decorative parts are integrated with the mobile phone case through injection molding. Because the decorative layer is injected into the inside of the mobile phone case, it eliminates contact with the surface air, so it will never fade. And patterns and effects can be made on the decorative layer, not limited by the phone case, and the space for customization is very large. And the decorative layer can be printed on both sides to achieve the effect of two-layer patterns of different heights.

Deep customization: Because the decorative layer can be placed inside the phone, it can support various effects. In theory, all the effects you can think of that can be applied to a flat surface can be applied to the decorative layer. At the same time, the material can be made into transparent, translucent, frosted and other textures. The shape can have a unique appearance.

Low cost in large quantities: The investment in imd mobile phone cases is only slightly higher in the initial stage. With mass production, the unit price of each mobile phone case is getting lower and lower, so if there is a need for large-volume shipments, you must choose imd mobile phone cases.

diy Glue phone case

Glue phone cases use special glue to stick the shape on a basic phone case. You can stick your favorite small parts on the case, or you can reshape it yourself with hot melt glue. The more mature solution currently is cream glue.

Features

DIY: You can make the shape according to your own preferences, and it is very three-dimensional.

sticker phone case

Sticker mobile phone case is to stick stickers with various effects on the back of the mobile phone case to achieve the purpose of DIY mobile phone case

Stickers are the cheapest way to brand

by effect

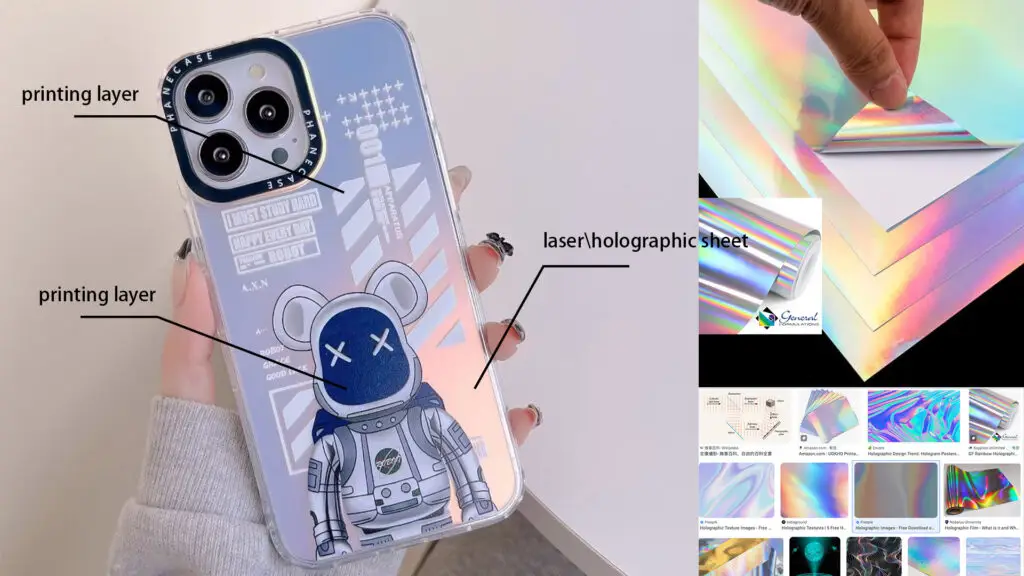

Holographic Phone Case

A holographic mobile phone case refers to a mobile phone case that uses holographic sheets. The holographic sheet can refract light to the maximum extent at different angles, so it will give people a glowing effect. Inject the holographic sheet into the mobile phone case, and you can Cell phone cases achieve this effect.

Glitter Phone Case

Add glitter powder to the inside of the phone case to get a shiny effect.

Gold Phone Case

The gold effect mobile phone case uses gold plating on the surface of the mobile phone case to achieve a real gold effect while maintaining hardness. If it is made of real gold, special materials need to be added for mixing.

Electroplating Phone Case

Electroplating is an electrochemical process that deposits a thin layer of metal on a metal or plastic substrate. Electroplated phone cases help avoid corrosion and give them a hard surface and an attractive decorative finish

Color Electroplating Phone Case

As the name suggests, it is to add color to the electroplating effect

Dimond Phone Case

Diamond mobile phone cases are inlaid with diamonds on the mobile phone case. You can choose to inlaid with Mozambican diamonds or real diamonds.

By use

mirror phone case

Adding a mirror design to the mobile phone case eliminates the trouble of carrying a makeup mirror. You can look in the mirror anytime and anywhere. A must-have mobile phone case for beauty lovers.

wallet phone case

Adding a wallet to the back of the phone case saves you the trouble of carrying a wallet. There are several ways to add a wallet to the phone case.

1. Make the wallet onto the back of the mobile phone case. The mobile phone case is the wallet.

2. Make a magnetic wallet separately. The wallet can be separated from the phone case and stuck together as needed.

3. Put the wallet inside the mobile phone case. Open and close the phone case and wallet.

phone case with card-holders

Add a card holder behind the phone case. You can refer to the wallet phone case for both manufacturing methods and effects.

Air bag phone case

A large number of airbag areas are designed inside the mobile phone case to maximize the anti-fall performance.

screen phone case

Add a screen to the back of the phone case, and you can change your favorite pictures through the app

power bank phone case

Add a power bank to the back of the phone case

led phone case

A fill light was added to the camera part of the mobile phone case, and the back shell was made into a laser sheet effect. The basic mobile phone case and components were manufactured through injection molding. Put the PCB board inside the phone case and reverse power supply.

How to choose a mobile phone case

Clarify needs

Before choosing a mobile phone case, you must clearly understand your needs. Is it to reduce battery consumption? Or to prevent falling? Or want to start a phone case business to make profits? Or maybe you are customizing a gift for someone. Only by clarifying your own needs can you choose a mobile phone case that suits you.

Understand the pros and cons of each style

After clarifying your needs, you can learn about all the styles of mobile phone cases that meet your needs, and understand them as comprehensively as possible, which will help you get the best choice.

Prepare a budget

After the above two points are determined, it is time to look at how much budget you have in your pocket, and then make the final selection based on the budget.

After the above steps, we believe that you will be able to choose a mobile phone case that best suits you.

Summary:

No matter which of the above mobile phone cases it is, casefty can customize it for you. We have many years of manufacturing experience in this industry. Can help you realize your mobile phone case business.